All data

centrally stored!

- Reaching for the sky.

Machine connection

& your benefits!

Machine information

Real-time recording

MDC provides you with real-time information from production. It is important that this data can be used as a supplier for further applications.

Data capture

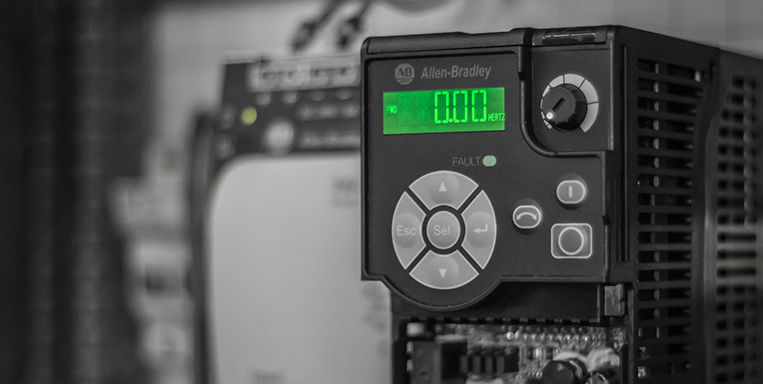

The use of modern control systems from all well-known machine manufacturers now supports numerous fieldbus and communication protocols. The best known protocols are: S7Com, MODBUS, CAN, MQTT, HTTP, OPC UA etc.

More All-In-One solutions

Machine/Shop-Floor data capture (MDC/SFDC) methods

Operating data is defined at various points. All data, be it of people, machines or transport equipment, are recorded and passed on.

Machine information «ONLINE»

With machine data capture (MDC), they can obtain an overview of production directly on their workstation at any time. Find out about the operating status of the machines or machine groups. Important key figures are immediately visible with a mouse click. In addition to machine availability, OEE results can also be read.

Real-time capture - MDC as central data supplier

MDC provides you with real-time information from production. It is important that this data can be used as a supplier for further applications. This is especially true for monitoring and alerting. Other applications such as maintenance, servicing and traceability receive input from the PDC data.

Data capture

The use of modern control systems from all well-known machine manufacturers now supports numerous fieldbus and communication protocols. The best known protocols are: S7Com, MODBUS, CAN, MQTT, HTTP, OPC UA etc.